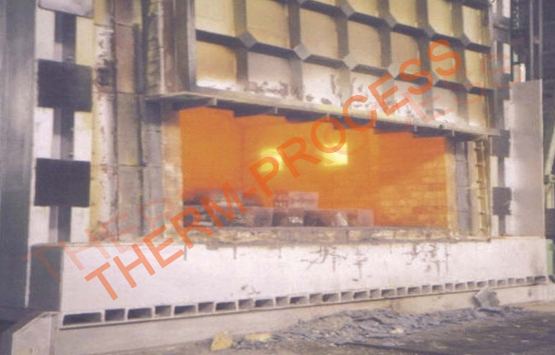

Forging Furnace - Chamber Furnace

Forging Furnace - Chamber Furnace

- For pre heating of billets and ingots forging furnaces are used

- The temperature maintained inside these furnaces is around 1200 to 1250 �c

- An open fireplace system is used through which most of the heat is transmitted via radiation.

- The Furnace operate around 16 to 18 hours a day, capacity can be vary from 250 Kg to 30 Ton per batch.

- The Operational time cycle in forging furnace is divided into Heat up Time, Soaking Time and Forging Time.

- The Consumption of fuel depends upon type of feed and number of reheat required.

- With Newly VENEERING INSULATION TECHNOLOGY it possible to reduce fuel consumption up to 50 % and increases the refractory life and production rate with faster start up heating time with low capital investment.

- Depend on the charge specification we can also suggest the Pusher Furnace for forging