Aluminum Melting / Holding Furnace ( Skelner Furnace)

Aluminum Melting / Holding Furnace ( Skelner Furnace)

This melting and holding furnace is designed for continuous operation and is suitable for aluminum die casting aluminum casting industries

Equipped with” Therm Process’s Super Low Speed Luminous Flame Burners” in the melting furnace. Electric heaters are used in the holding furnace.

Fuel Used - L.D.O. / F.O. / Producer Gas/ Coal Gas / Natural Gas

Fuel Consumption - 75 to 90 Liter. / Ton of F.O.

Capacity - 300 Kg to 30 Tons

Attractive Features

No Hard Oxidation Material, the temperature in the holding chambers is kept at about 50° c higher than that of molten metal. This minimizes possibility of formation of hard oxidation of material caused by over temperature condition.

Low Energy Cost

Long Heater Life

Low Maintenance cost & small space utilization

Superb working condition

We offer following type of Aluminum Melting Furnace

1. Tilting Type melting Furnace (Manually / Hydraulically Operated)

2. Tower Type Aluminum Melting Furnace

3. Crucible Type Holding Furnace

4. Stationary Aluminum Melting / Holding Furnace

Stationary Type Aluminum Melting Furnace

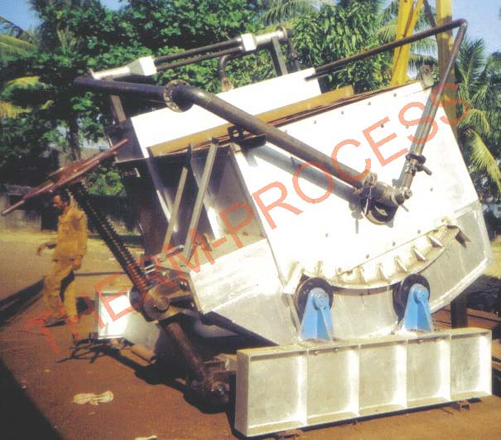

Tilting Type Aluminum Melting Furnace

Aluminum Melting Furnace - Mechanical Tilting

Tower type melting Tilting Furnace

Tower Melting Furnace for Aluminium

Aluminium Melting/ Holding Furnace

• Type of Furnace : Hydraulic Tilting Type Aluminium Melting Furnace

• Bath Capacity : 6000 Kg.

• Charging Temp. : Ambient, 30° C

• Furnace Temperature : 1000° C Max.

• Melting Rate : 1500 Kg. / hr.

• Mode of Charging : Manual through Hydraulic operated

Charging Door

• Mode of Discharging : Hydraulic Lifting Lip Axis pouring spout

• Fuel : LPG